Think about making stuff today. Not just the factory part. All of it. The idea. The design. The drawings. The changes. The approvals. The tests. The versions. The suppliers. The fixes. The updates.

Now picture doing all that with emails. And shared folders. USB drives. Files named like “final_v3_revised_last_real_final”.

Sounds messy, right? It is.

That’s real life for many teams.

Here’s where Windchill comes in.

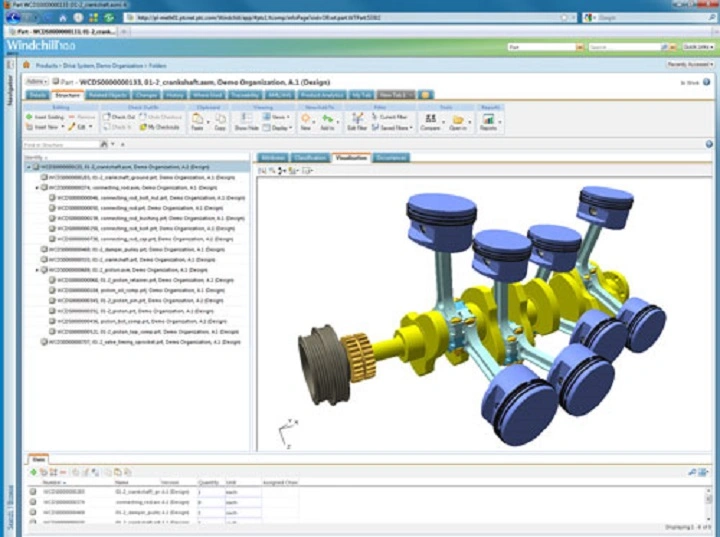

Windchill isn’t a design tool. Not like CAD. It’s not an email. Not a spreadsheet. It keeps product info neat. Under control. Easy to track. From first idea to final product. And beyond.

This guide explains Windchill simply. No big words. No sales talk. Just what it is. How it works. Who uses it, why it matters.

What Is Windchill Software?

Windchill is a PLM system. PLM means Product Lifecycle Management.

What’s that mean? Simple.

PLM software handles all product data. Through its whole life. Design files. Drawings. Parts lists. Papers. Change requests. Approvals. Versions.

Think of Windchill as a home base. All product info lives there. Everyone uses the same data. Everyone sees the latest version. Nothing gets lost in emails.

Put simply? Windchill controls product data.

Why Windchill Software Exists

Products today are complex. Even simple ones have tons of parts.

Teams work all over. Suppliers too. Changes happen daily. Rules must be followed. Mistakes cost a lot of money.

Without a system? Lost files. Wrong versions. Bad changes. Total confusion.

Windchill fixes these problems. It brings order. Control. Clear view of everything.

The right people see the right data. At the right time.

Who Uses Windchill Software?

Most engineers and factories use Windchill.

Mechanical engineers manage CAD files with it. Electrical engineers track parts and docs. Product managers watch over everything.

Factory teams need it for parts lists. Quality teams track compliance papers. Supply chain folks work with suppliers through it.

Who else? Car makers. Plane builders. Heavy machine companies. Electronics firms. Medical device makers. Equipment builders.

Got complex products? Got rules to follow? Windchill fits.

Core Idea Behind Windchill

The main idea? Super simple.

One source of truth.

No more multiple file versions floating around. Windchill keeps one controlled version. Changes follow rules. Approvals get recorded. History stays saved.

You always know stuff. What changed, who changed it, when and why.

That tracking? That’s PLM’s heart.

Managing Product Data in Windchill

Windchill stores data in a smart way.

CAD models. Drawings. Documents. Specs. All linked to their product. Not just stored. Related.

Like this. A part drawing links to a part number. That number links to a parts list. That list links to an assembly.

See? Everything connects.

Teams get how it all fits.

Version and Revision Control

Version control? Super important in Windchill.

Someone edits a file? Windchill tracks it. Old versions? Not deleted. Saved for later.

Revisions mean approved changes. Not quick edits.

This stops mistakes. Like factories using old drawings. Or suppliers getting wrong data.

Change Management Made Simple

Changes happen.

Design flaws pop up. Customers want new stuff. Rules change. Costs need cutting.

Windchill handles changes through set steps.

Someone makes a change request. It gets reviewed. Approved or not. Done. Written down.

Everyone knows what’s changing. And why.

No confusion later. No blame game.

Bill of Materials Management

The BOM matters big time. BOM means Bill of Materials.

It lists all parts to build something.

Windchill manages engineering BOMs. Links them to factory BOMs. Design matches production.

Part changes? BOM updates. Production stays aligned.

Collaboration Across Teams

Windchill helps teams work together.

Many teams. Same product. No overwriting work. Access controls who sees what.

Suppliers get limited access. Partners work safely. Global teams stay synced.

Less emails. Fewer meetings. Less confusion.

Windchill and CAD Integration

Windchill loves CAD software.

Engineers save designs right into Windchill. From their CAD tools. The system handles versions. And relationships.

Less manual work. Fewer mistakes.

Designers design. Not managing files.

Compliance and Quality Control

Many industries have strict rules.

Windchill stores compliance docs. Test results. Certs. Approval records.

Audits? Easy. Everything’s documented. And trackable.

Super important for planes. Medical devices. Cars.

How Windchill Works in Real Life

Picture this. An engineer updates a part.

They check out the file. Make changes. Save it back. Windchill makes a new version.

Change requests go up. People review. Approve.

Once approved? Factory sees updated BOM. And drawings.

No emails. No mix-ups. No wrong files.

That’s Windchill working smoothly.

Windchill vs PDM

What’s the difference? PDM vs Windchill?

PDM means Product Data Management. It manages CAD files. And versions.

PLM like Windchill? Goes further. Covers processes. Changes. Compliance. Team work. Lifecycle stuff.

PDM is part of PLM. But PLM’s way bigger.

Windchill vs Other PLM Tools

Windchill has competition. Other PLM systems exist.

What makes Windchill special? Deep engineering focus. Strong CAD links. Scales for complex products.

Big engineering companies often pick it.

Challenges of Using Windchill

Windchill’s powerful. But not simple.

Setup takes time. Training matters. Processes need defining.

Bad setup? Users feel lost.

Success needs training. And boss support.

Works best when teams follow rules. Use it daily.

How Long Does It Take to Learn Windchill?

Basic users? A few days for main tasks.

Advanced users? Admins? Process owners? Weeks or months.

Learning never stops. Products change. Processes evolve. Learning continues.

Cost Considerations

Windchills cost a lot of money. It’s enterprise-level.

Licenses. Setup. Custom work. Training. All add up.

But for complex products? Worth it. Fewer errors. Faster development. Better compliance.

Career Value of Windchill Skills

Windchill skills pay off. In engineering. In manufacturing.

PLM admins wanted. Config specialists too. Change managers. System analysts.

Know Windchill? Move up easier. Into leadership. Process roles.

Strong career boost. In product industries.

Who Should Use Windchill?

tool. It’s the base for organized product work.

Brings order to chaos. Control replaces guessing. Connects people. Data. Processes.

Build complex products? Windchill keeps everything aligned. From idea to delivery.

Controlled data means faster teams. Fewer mistakes. Better quality.

That’s Windchill’s real value.